Maintaining Generators for Critical Facilities

Maintaining Generators for Critical Facilities

For critical facilities such as hospitals, data centres, emergency response hubs, and manufacturing plants, reliable power is not optional, it’s essential. Even a brief power outage can compromise patient safety, disrupt communications, damage equipment, or cause financial and operational losses.

That’s why generators play such a vital role in the continuity and resilience of critical facilities. However, owning a generator is only half the equation. To ensure performance when it matters most, routine maintenance is key.

Why Maintenance Matters for Critical Facilities

Generators are designed to deliver dependable backup power in emergencies, but without regular upkeep, they can fail at the worst possible time. For facilities where lives, data, and essential services are on the line, this is not a risk worth taking. Key reasons why maintenance is non-negotiable:

• Reliability: Ensures generators start and run smoothly during an outage.

• Longevity: Prevents costly breakdowns and extends the lifespan of the unit.

• Compliance: Many industries are required by law or regulation to maintain standby power systems.

• Cost Savings: Proactive care reduces emergency repair costs and downtime.

Essential Generator Maintenance Tasks

1. Routine Inspection

Visual inspections should be carried out regularly, weekly or monthly, depending on usage. Look for leaks, signs of corrosion, loose connections, or fluid levels that need topping up.

2. Fuel System Checks

Fuel is often the weak link in generator performance. For diesel units, fuel can degrade over time, causing contamination and blockages. Regular fuel polishing, tank inspections, and filter changes are critical.

3. Oil and Filter Changes

Like any engine, a generator relies on clean oil to operate effectively. Change oil and filters at intervals recommended by the manufacturer to prevent premature wear.

4. Cooling System Maintenance

Check coolant levels and inspect hoses, belts, and radiators for wear or blockages. Overheating is a common cause of generator failure.

5. Battery Testing

A generator can’t start if the battery fails. Test batteries regularly, clean terminals, and replace them every 2–3 years or as needed.

6. Load Bank Testing

Simply running a generator without a load isn’t enough. Load bank testing ensures the generator can handle its rated capacity under real conditions, preventing “wet stacking” and ensuring readiness.

7. Exercising the Generator

Generators should be run periodically, even when not in use, to keep moving parts lubricated and systems operational. This also helps identify minor issues before they become major failures.

Best Practices for Critical Facility Maintenance

• Follow a Schedule: Develop a written maintenance plan with intervals for daily, weekly, monthly, and annual tasks.

• Document Everything: Keep detailed logs of inspections, tests, and servicing for compliance and performance tracking.

• Train Staff: Ensure on-site personnel know basic operation and emergency procedures.

• Partner with Experts: Work with certified technicians for servicing, load testing, and complex repairs.

Common Maintenance Mistakes to Avoid

• Neglecting fuel quality: Contaminated or stale fuel can render a generator useless.

• Skipping load tests: Without testing under load, you can’t guarantee readiness.

• Ignoring minor issues: Small leaks or loose connections can escalate into critical failures.

• Failing to plan for parts: Keep spare filters, belts, and fluids on hand for quick fixes.

Maintaining Confidence Through Preparation

Critical facilities can’t afford power interruptions, and maintaining your generators ensures that you’re always ready for the unexpected. A well-maintained generator is more than just equipment, it’s peace of mind, a safeguard for operations, and a lifeline in emergencies.

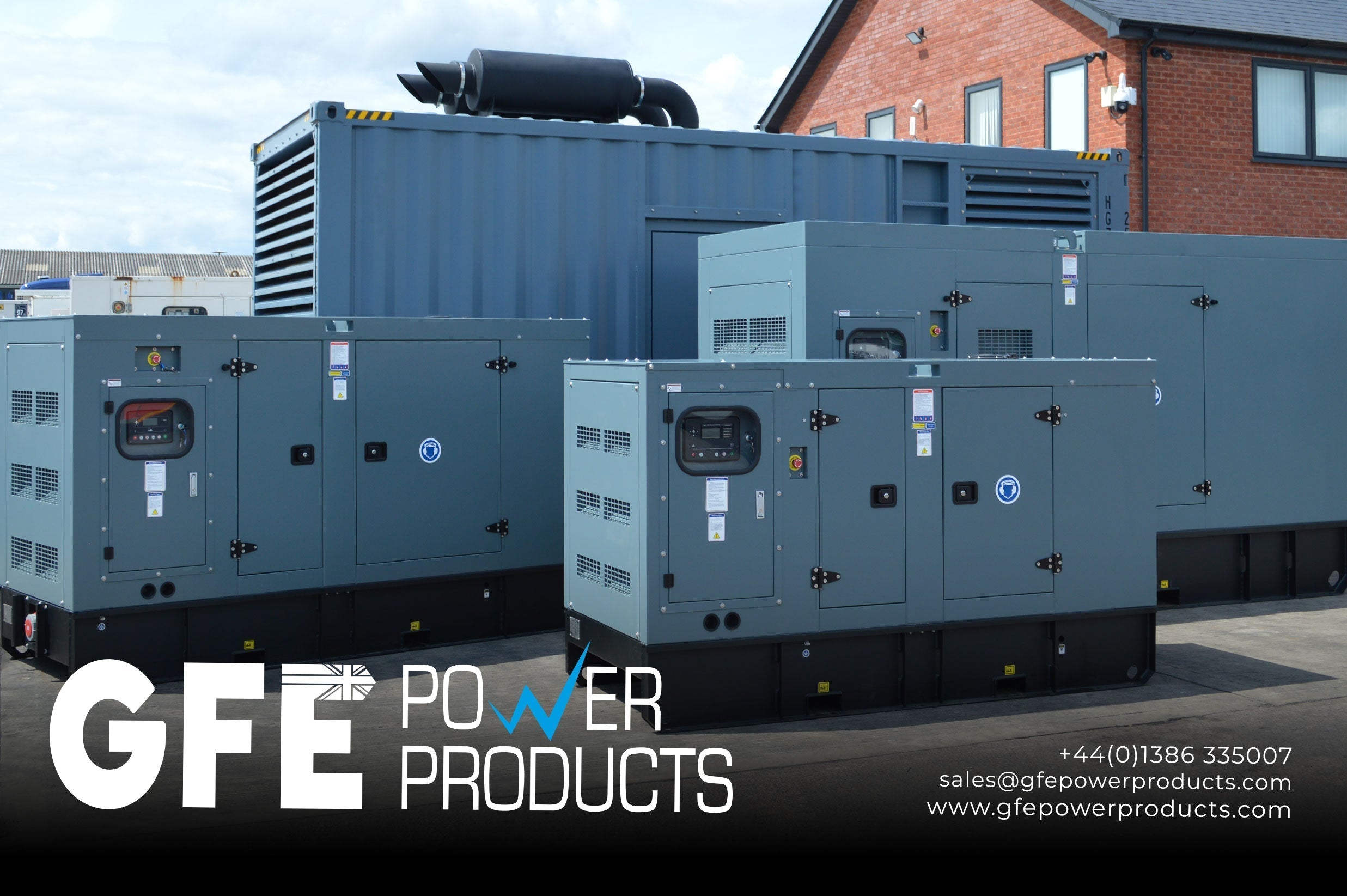

Partner with GFE Power Products for Generator Reliability

At GFE Power Products, we know that critical facilities demand uncompromising reliability. That’s why we supply durable, high-performance generators, such as GFE Baudouin Powered Diesel Generators and GFE Cummins Powered Diesel Generators, built to withstand the most demanding conditions. Discover our complete product range of reliable power solutions designed to keep your operations running without interruption.

Our team can help guide you on maintenance best practices, provide the right equipment, and ensure your facility has the backup power it needs to keep running smoothly.

Contact us today and explore our full range of new diesel generators and ensure your critical facility is always prepared.

Phone: +44 (0)1386 335007

Email: sales@gfepowerproducts.com