The Importance of Regular Generator Maintenance

Generators are the unsung heroes of modern infrastructure. Whether they’re supplying backup power to a hospital, keeping data centres online, or powering tools on a remote construction site, generators need to perform instantly and without fail. But performance doesn't happen by accident- it’s built on a foundation of routine, strategic maintenance.

At GFE Power Products, we don’t just supply high-quality diesel generators, we help businesses keep them running at peak performance. In this post, we explore why regular maintenance is essential and how it can protect your investment.

Why Generator Maintenance Is Essential

Like any mechanical system, generators suffer wear and tear over time. Regular maintenance isn’t a luxury, it’s a necessity that ensures reliable operation during emergencies, extends the lifespan of your equipment, improves fuel efficiency, and keeps you compliant with warranties and industry regulations. Neglecting basic upkeep can lead to expensive repairs, operational disruptions, and even complete system failure.

What Can Go Wrong Without Maintenance?

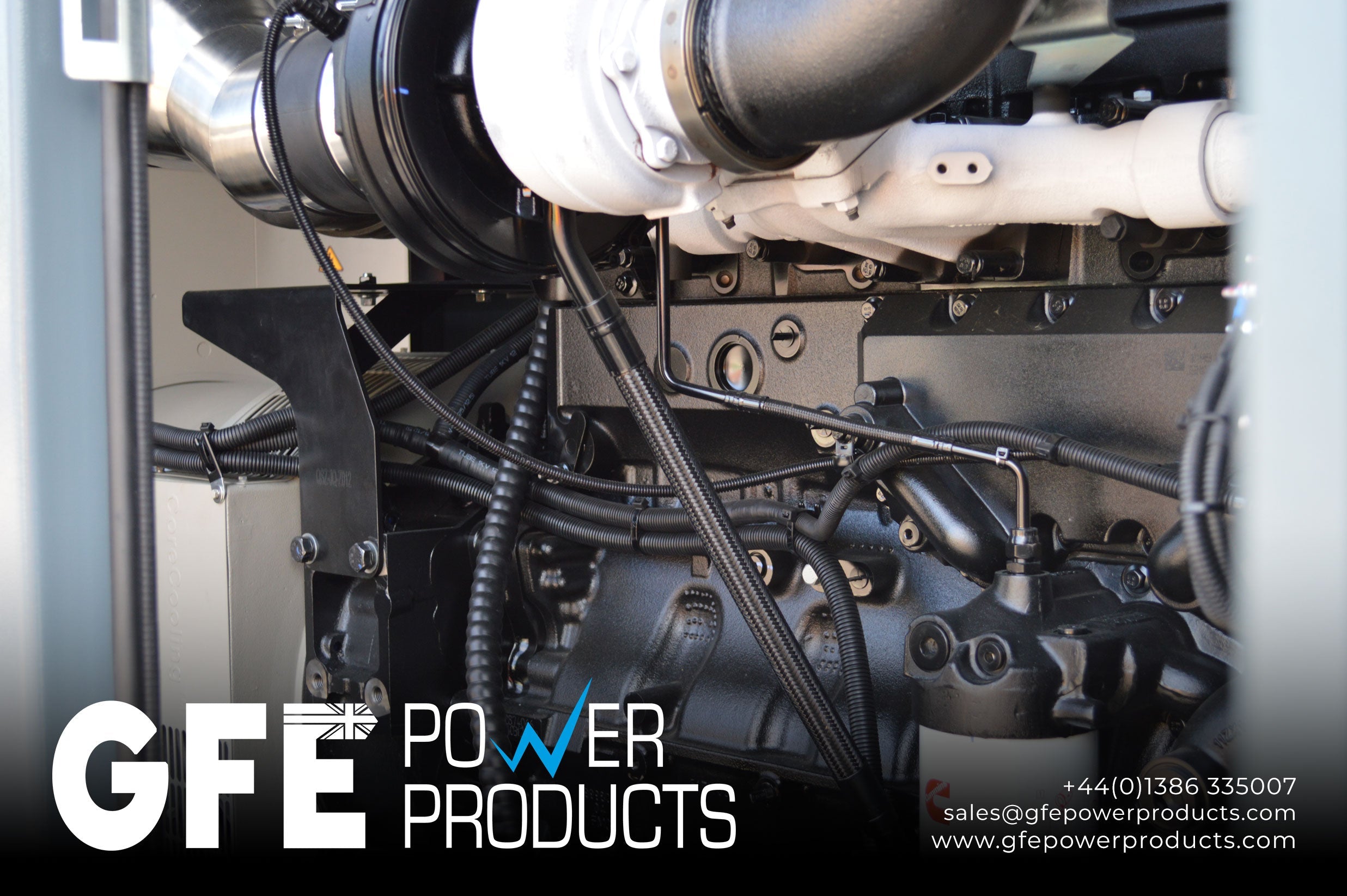

Skipping scheduled servicing opens the door to avoidable failures. Batteries can lose charge or corrode, fuel can degrade and clog lines, and coolant systems can overheat due to clogged radiators or low levels. Over time, oil can lose its viscosity, reducing its ability to lubricate the engine, while sensors and control panels, especially on advanced engines like Baudouin, can deliver faulty readings if not calibrated regularly. These issues, individually or combined, can bring a generator to a halt when you need it most.

Key Elements of a Generator Maintenance Plan

A complete maintenance plan should address the entire generator system. At the engine level, this includes regular oil and filter changes, monitoring coolant levels, and replacing worn belts or hoses. Air and fuel filters must be checked and swapped when necessary to avoid airflow and fuel delivery issues.

Your generator’s electrical system deserves equal attention. Batteries must be tested for voltage and inspected for terminal corrosion. The starter motor should be assessed periodically, and load bank testing is recommended, especially for standby units, to ensure readiness under operational loads.

Fuel systems benefit from regular checks to prevent contamination. Inspecting tanks and lines, removing water or sediment, and replacing fuel filters are essential steps. For digital generators, don’t neglect the control panel, review alarms and fault logs, update firmware if applicable, and recalibrate any sensors that are drifting from specification.

Finally, a visual inspection of the entire unit ensures that the exhaust system is intact, mounting points are secure, and airflow is unobstructed. Keeping the generator clean, dry, and free from debris helps prevent overheating and corrosion.

Frequency of Maintenance

Maintenance intervals vary based on generator type and usage. For standby generators, a monthly visual inspection and a monthly loaded run test are standard. A full service is recommended every 6 to 12 months, depending on the environment and usage frequency. Prime power generators, which operate for longer and more frequent periods, should typically be serviced every 250 to 500 hours of operation.

At GFE Power Products, we customise maintenance schedules to match each client’s specific needs, ensuring no unit is over- or under-serviced.

Benefits of a Preventive Maintenance Strategy

Preventive maintenance is far more cost-effective than reactive repairs. Addressing small issues early prevents them from snowballing into major breakdowns. Businesses benefit from reduced downtime, lower repair bills, and extended equipment lifespan.

It’s also a matter of safety. Fuel leaks, frayed wires, or malfunctioning sensors can pose serious hazards if left unchecked. Scheduled servicing improves workplace safety and gives you peace of mind knowing your equipment will operate reliably when needed.

From a financial standpoint, regular maintenance preserves your asset’s value and performance, reducing the total cost of ownership over time.

Why Work with GFE Power Products?

- We don’t just supply top-tier diesel generators, we support them for life. Our experienced team offers tailored maintenance schedules, on-site servicing, and diagnostics designed to keep your equipment in peak condition.

- We carry genuine OEM parts, including components for Baudouin-powered units, and offer load bank testing, emergency servicing, and full support contracts to suit businesses of any size.

- Whether you manage a single standby generator or a full fleet, GFE Power Products is your long-term partner in reliable power.

Regular generator maintenance isn’t just good practice, it’s essential. It ensures your power supply is ready when you need it, maximises the value of your investment, and protects your business from unnecessary disruption.

Need help building a maintenance plan for your generator? Reach out to the team at GFE Power Products.

Let us help you power with confidence.

Phone: +44 (0)1386 335007

Email: sales@gfepowerproducts.com